Phased Array UT - PAUT

PAUT is an advanced inspection method used to detect discontinuities components such as cracks and flaws.This method is is considered very powerful and flexible in detecting defects at it is possibile to control few parameters such as beam angle and focal length. Phased Array UT - PAUT inspection can also be used for variety of applications like measuring wall thickness and corrosion testing.

Phased array UT - PAUT is used in wide range of applications,

- Weld Inspection

- Corrosion Mapping

- Thickness measurements

Principle of Phased Array UT - PAUT

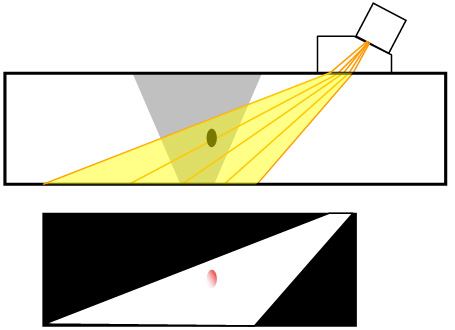

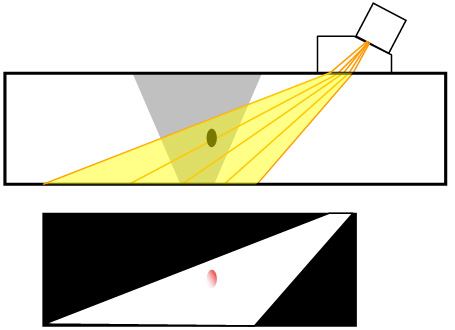

The PA probe consists of many small ultrasonic transducers, each of which can be pulsed independently. By varying the timing, for instance by making the pulse from each transducer progressively delayed going up the line, a pattern of constructive interference is set up that results in radiating a quasi-plane ultrasonic beam at a set angle depending on the progressive time delay. In other words, by changing the progressive time delay the beam can be steered electronically. It can be swept like a search-light through the tissue or object being examined, and the data from multiple beams are put together to make a visual image showing a slice through the object.

Time-of-flight diffraction (TOFD)

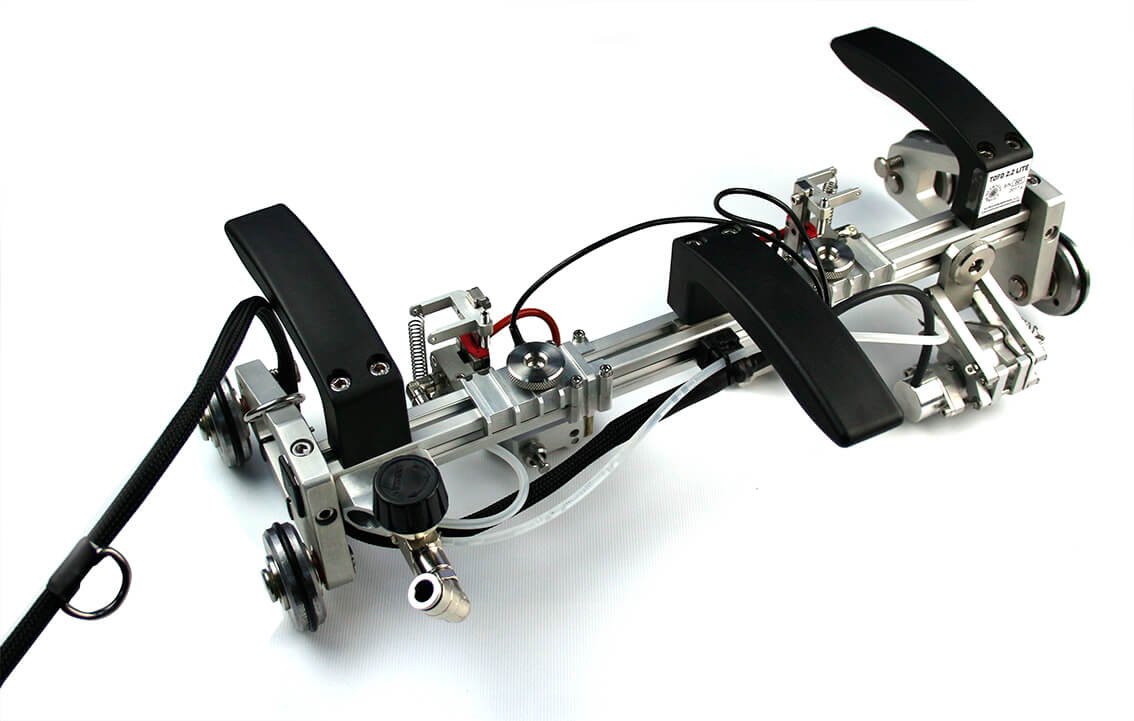

Time-of-flight diffraction (TOFD) method of ultrasonic testing is a sensitive and accurate method for the nondestructive testing of welds for defects. Phased Array with TOFD combination is commonly used to inspect pipeline welds.

The Time-of-Flight Diffraction (TOFD) method can be regarded more and more as a standard NDT technique in an increasing number of countries. Nevertheless, there is still a considerable amount of development work going on.

Time-of-Flight Diffraction Ultrasonic Testing is among the most modern testing methods for the detection of imperfections and defects in materials. Conventional Ultrasonic Testing uses sound reflection. ToFD testing measures the time-of-flight of an ultrasonic pulse to determine the position of a reflector. The application of this method is fast and extremely accurate. This has resulted in an increasing popularity over the last few years.

Aptest

Aptest