Our Comprehensive Cryogenic Valve Testing Process

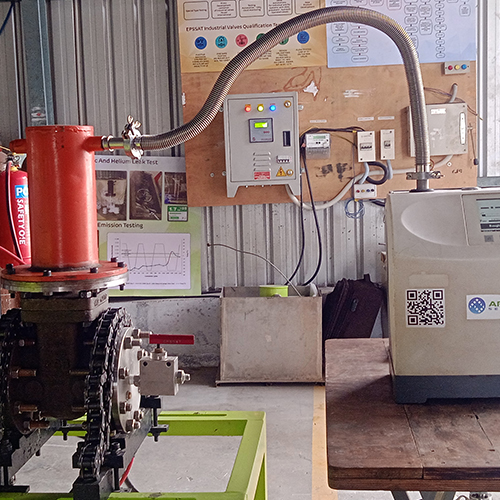

Our dedicated team employs advanced techniques and cutting-edge equipment to ensure the integrity and reliability of your valves. Our comprehensive testing process includes:

- Pre-Testing Inspection: We begin with a thorough examination of your valves to assess their condition and identify any visible defects.

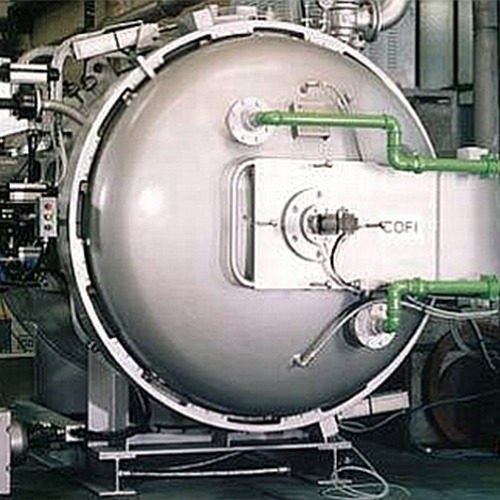

- Cryogenic Testing: Valves are subjected to extreme low temperatures, simulating real-world cryogenic conditions, to assess their performance under stress.

- Leak Detection: We meticulously inspect valves for any signs of leakage, ensuring their ability to maintain a tight seal even in cryogenic environments.

- Compliance Assurance: Our testing procedures are designed to meet industry standards and regulatory requirements, guaranteeing that your valves meet safety and performance standards.

- Detailed Reporting: You'll receive a comprehensive report detailing the results of our Cryogenic Valve Testing, including any necessary recommendations or actions.

Our Commitment to Quality

At Aptest NDT Services, quality is our top priority. We adhere to strict testing protocols and invest in ongoing training and certification for our technicians to ensure the highest level of accuracy and reliability.

When it comes to Cryogenic Valve Testing, trust the experts at Aptest NDT Services. We understand the critical importance of valve performance in extreme low-temperature environments, and our testing services are designed to provide you with the confidence and assurance you need.

Aptest

Aptest